Wool is cool

A Wool Experience.

Wool is without doubt, my favourite material. It has a beautiful, strong appearance, it is very easy to work with, long-lasting and comfortable.

I always liked wool but when I had the opportunity to work for a wool company, I truly discovered the mysteries of the wool production and felt in love even more.

A couple of years ago, I spent a few months at a little wool factory in Spain. Honestly I didn’t know what to expect before arriving there. I had never been before in a textile factory and actually the wool was a very unknown material for me. José Vicente, the owner of the family company J.G. Tejeda welcomed me, I didn’t know then that a love story with wool was about to start.

A little bit about wool

Wool is obtained mainly from sheep but also from other animals such as goats (cashmere and mohair), muskoxen, rabbits (angora) or llamas. Wool has been used since the stone age and has survived the centuries as one of the most used textile fibre due to its great qualities:

- Natural fibre

- Renewable

- Biodegradable

- Natural insulator

- Breathable

- Resilient and elastic

- Trans-seasonal

- Easy care

- Odour resistant

- No allergies

Wool is very nice and healthy to have on your skin. It is also very easy to take care. While it doesn’t need much washing due to its inner antibacterial qualities, modern washing machines come with wool programs that will make it easier for you if your fgarment needs a wash. Until now, no man-made fibre has been able to duplicate all of the properties of natural wool

You can find further information in the Campaing for Wool Organisation and Wikipedia.

A historical textile center

J.G. Tejeda, the wool factory that hosted me is located in the Spanish middle-west, in a town called Bejar in the province of Salamanca. Sorrounded by high mountains this town was in the old times famous for being the second most important textile center in Spain. It is an amazing place if you like nature and sports (there’s a ski resort). Bejar was once a prosperous town thanks to the hundreds of textile factories that progressively opened there since the 18th century.

The basics

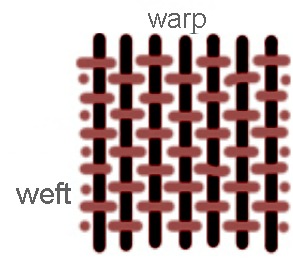

Before I continue I would like to explain the basics of a fabric for those of you that are not familiar with  textiles. Wool fabrics are generally woven on a loom, which is a device that holds the warp threads in place while filling threads are woven through them. The way the warp and filling threads interlace with each other is called the weave. A wool fabric is a woven material compose by the warp and the weft. To obtain the different designs and details, all you have to do is too play with the way the threads will be placed when the fabric is weaved.

textiles. Wool fabrics are generally woven on a loom, which is a device that holds the warp threads in place while filling threads are woven through them. The way the warp and filling threads interlace with each other is called the weave. A wool fabric is a woven material compose by the warp and the weft. To obtain the different designs and details, all you have to do is too play with the way the threads will be placed when the fabric is weaved.

Designing fabrics

The first thing I learn at J.G. Tejeda was how to design fabrics thanks to Enrique, textile engineer. I have to say that never before I thought there would be so many possibilities to create wool fabrics.

The first thing I learn at J.G. Tejeda was how to design fabrics thanks to Enrique, textile engineer. I have to say that never before I thought there would be so many possibilities to create wool fabrics.

At J.G. Tejeda they use a computer program that makes it easier to combine the threads and allows you to see in forehand what the final result would be.

The process is simple.You have a menu with all the different threads available at the factory, the patterns they can follow and the finitions the fabric can follow to give a specific look/touch. It also calculates the algoryhtms for the threads crossing.

Despite making things easier, the program doesn’t make miracles. You still need to know a lot about yarn, its different qualities, how threads are weaved and textile in general. Thanks to the great teacher I had these are some of the samples I created during my time at J.G. Tejeda:

It is all about the yarn

Once you have designed your fabric on the computer it is time to make it real. The next step is tochoose the right threads. One of the amazing things about J.G. Tejeda is the personalize service they propose to their clients. They can create unique exclusive fabrics which starts by creating their own yarn in specific colours, thickness and appearance. Below you can see Paco chosing the right threads at the storage room.

Now we can prepare the base of the fabric. That is called the warp and it’s the set of lengthwise threads that are held in tension on a frame.

Mari Luz was the woman in charge of this task at the J.G. Tejeda factory. Here you can see her brushing the yarn to prepare it for the weaving machine.

Weaving

The warp is ready. Now it’s time to pass it to the weaving machine and prepare the weft yarn. Installing the warp in the weaving machine is a meticulous process since every thread has to be attached to the threads that were previously weaved. We are talking about hundreds or thousands of threads following an specific pattern.

This is how the warp of one of my creations looked while Agustín -the man in charge- was knotting the yarn:

The weaving machine is really the symbol of textiles. The sound of the weaving machines is so unique and standing there, looking how the threads cross each other until you get the yarn, is kind of hypnotizing.

No mistakes allowed

When the fabric comes out of the weaving machine it is not ready yet.

Right after coming out of the weaving machine it has to be supervised to detect any possible mistake. Like missing, broken or missplaced threads.

In the case a mistake is found, to avoid wasting the whole roll of fabric, it is send to the darning ladies who would repair it just with a needle and thread. This is a very tedious and laborious task. The best darning experts are trained since a very young age to spot the errors in a fabric and repair them to perfection very quick. The result is amazing, they repare the fabric to perfection.

Sizing

The last step before getting the final fabric is the sizing. In the case of J.G. Tejeda, they send their fabrics to a neighburing company specialzed in sizing. Sizing is probably the most important part of the process since it can improve the look and qualities of the fabric or just completely destroy.

What is Sizing?

In order to reduce the fabric’s breakage and give it the desired look, the fabric has to follow a combination of numerous treatments and exposure to different substances (cyclic strain, flexing, abrasion at various loom parts and inter yarn friction) . The sizing gives it as well the lenght and the weight specified for each roll of fabric.

In order to reduce the fabric’s breakage and give it the desired look, the fabric has to follow a combination of numerous treatments and exposure to different substances (cyclic strain, flexing, abrasion at various loom parts and inter yarn friction) . The sizing gives it as well the lenght and the weight specified for each roll of fabric.

Ready to sew

Now the fabric is finished and ready to be used! Just one last verification, the experts will measure and weight the fabric to ensure that the final product is exactly what the customer or his designer wanted.

Now the fabric is finished and ready to be used! Just one last verification, the experts will measure and weight the fabric to ensure that the final product is exactly what the customer or his designer wanted.

There is no doubt that my days at the wool factory were one of the best experiences of my life. The amount of things I learnt not only about wool but about textile in general are a treasure. It is an incredible opportunity to be surrounded by people with such long experience in the textile industry but as well with an enormous passion for it. Also as a gift I brought with me a collection of wool fabrics designed by myself and quite a few meters of wool!

If you want to know more or you would like to contact J.G. Tejeda Factory, drop me a line.

Previous Post

Previous Post Next Post

Next Post

Always a good read.